WT-SMS-08 gantry crane safety monitoring and management system is a customized safety monitoring and management system equipment designed and manufactured for gantry cranes. Safety monitoring instruments specially designed and manufactured to meet the characteristics of port cranes such as prolonged use and frequent vibrations can provide comprehensive and reliable safety monitoring and management of cranes.

Product advantages:

WT-SMS-08 gantry crane safety monitoring and management system is a customized safety monitoring and management system equipment designed and manufactured for gantry cranes. Safety monitoring instruments specially designed and manufactured to meet the characteristics of port cranes such as prolonged use and frequent vibrations can provide comprehensive and reliable safety monitoring and management of cranes.

This system equipment not only meets the national standard "GB/T 28264-2017 Crane Safety Monitoring and Management System", but also performs simple recording and display of crane operations.

The system also performs in-depth analysis and processing of monitoring data to achieve, for example, hoisting brake hook monitoring and early warning, logical diagnosis of control faults, and the lifespan of key control components.

Function:

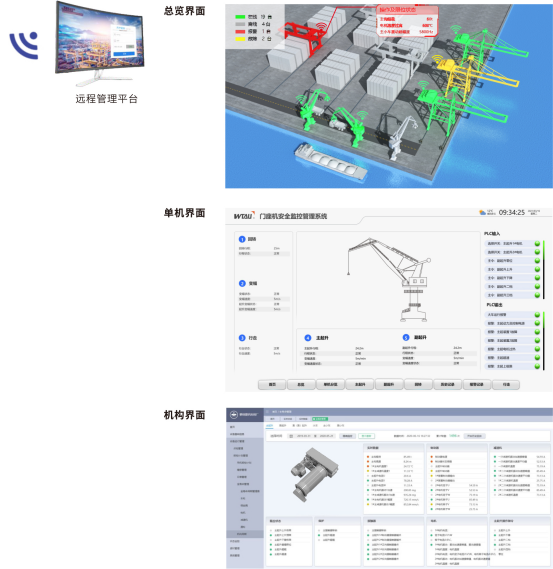

The real-time status and video images of the crane operation are remotely sent to the office for centralized monitoring (numbers, Chinese characters, graphics, curves, sounds).

Historical data storage, query, filtering and statistics.

Fault alarm reminder, storage, query, statistics.

Remote fault diagnosis based on real-time data and status, and fault analysis of historical data.

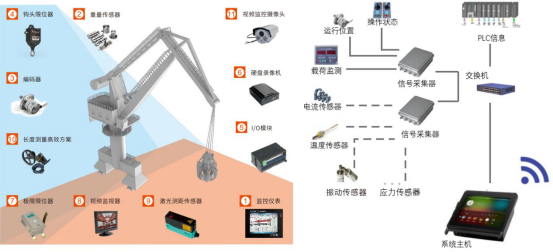

Structural layout: The system structure adopts distributed layout, digital transmission, double isolation between communications, optimizing the structure while preventing strong interference.

Host performance:

1. The host adopts an imported true-color 65,536-color TFT-LCD display, which can display parameters and status with numbers, Chinese characters, and graphics. It can also reflect the monitoring status through color changes, and the picture is realistic.

2. Use touch-type prompt sound operation to prevent dust from entering the key gaps or the hidden dangers of key film rupture.

3. Extra large storage capacity for more than 6 months.

4. Equipped with multiple RS232RS485 serial ports, USB, and Ethernet communication interfaces, and can remotely download and update upgrade programs.

5. The professional version of the metallurgical bridge crane safety monitoring and management system software can quickly and automatically correct, back up and restore data, making debugging simple and reliable.

Protection optimization:

Dust-proof box seals and stuffing boxes are standard to isolate metal dust, oxide film, smoke and other dust. The main circuit board uses military-grade electronic components, resistant to high temperature and extreme environments, with three-spray and three-proof paint, high-temperature aging, and vibration table testing.

Compatible with upgrades:

The professional-grade IO acquisition module is compatible with direct acquisition or communication with PLCs of various brands.

Remote real-time monitoring: The WT-CIMS-V2.0 safety monitoring and management system platform uses wireless transparent transmission technology to realize real-time remote transmission of driving safety monitoring and management data and video images to the office. Managers can learn about the crane in the office at the first time Real-time operating status, query historical operating data, and perform big data analysis on historical records. It brings convenience to safety management and saves management costs.

Application: The safety monitoring remote management platform supports the display of real-time data of each monitored crane in multiple modes and angles such as animation, text, graphics, etc. The interface realizes real-time online data, status monitoring and alarming of clusters, single machines, and institutions, and enables historical monitoring Data, alarm and fault records can be queried, analyzed, and reports generated. At the same time, the video on the crane can be synchronized and remotely monitored online in real time in the office.

![]() Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

Add.:No.6 Gangcheng Road,Yichang,Free Trade Zone(Hubei) China 443005

![]() 86-15507209968(whatsapp)

86-15507209968(whatsapp)